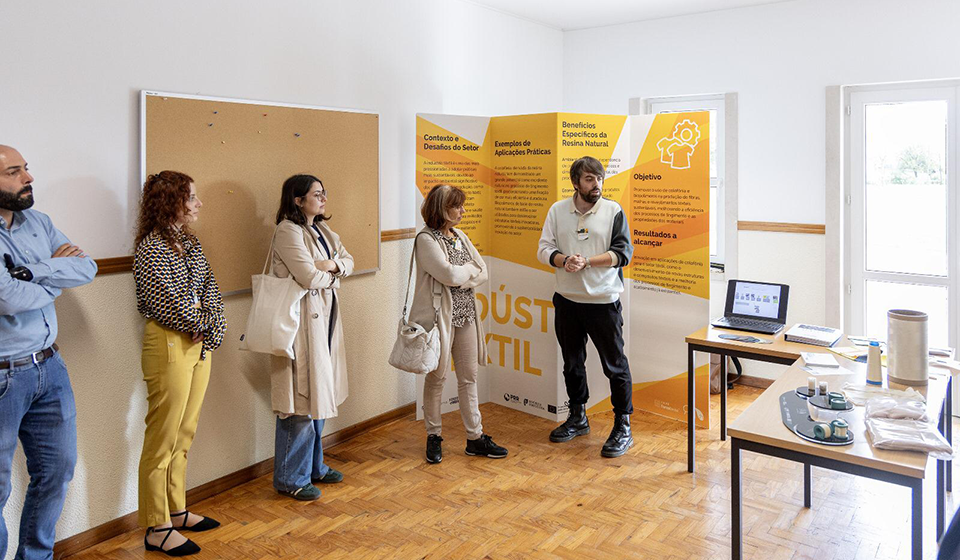

PAULO CADEIA, EXECUTIVE DIRECTOR OF TECMEAT Portugal’s national meat-producing and processing sector can be classified as a strategic and evolving sector, with characteristics that combine tradition, recognized quality, and challenges in terms of innovation, competitiveness, and sustainability. This is how Paulo Cadeia, executive director of TECMEAT, in an interview with iAlimentar magazine, characterizes the sector, who adds that Portugal is known for the production of high-quality meat, especially in the case of pork (including the iconic black pork) or beef through its native breeds. In addition, the executive warns of the need to increase training and continuous qualification in new technological practices, as well as to increase innovation and cooperation activities between companies and scientific entities. What led to the creation of TECMEAT?The creation of the Agri-Food Competence Center with a focus on the Meat Industry (TECMEAT) is essentially due to two points. The first, resulting from the high concentration of the meat processing industry that exists in the region where TECMEAT is implemented; the second, the vision of the Municipality of Vila Nova de Famalicão to verify that there was no competence center at a regional, and even national, level capable of developing innovation activities and technical and practical training activities specifically oriented to the meat processing industry sector. Thus was born TECMEAT, a private and non-profit association, whose mission is to enhance the increase in competitiveness and innovation of producing and processing companies in the meat sector through its scientific and technological development. In which areas does it operate? What services do you provide?Although more broadly, TECMEAT can operate in the entire agri-food sector, its main focus is on the meat sector and its processing. Through its Pilot Unit and its Microbiology Laboratory, TECMEAT can provide a set of services to the industry that includes technical and technological training in a pilot environment, support and consultancy in the development and characterization of new products and new processing techniques, or even in the provision of a wide range of analyses, tests, and quality control trials. In addition to these components, TECMEAT has also acted as a hub for the transfer and demonstration of knowledge to the industry in partnership with new product and process developments obtained from equipment goods companies and suppliers of ingredients and the most diverse consumables. In which research projects does TECMEAT participate? Are there prospects for new products to enter the market? When?Currently, TECMEAT participates in three projects of the RRP (Recovery and Resilience Program). He is actively involved in the VIIAFOOD agenda. led by Sonae, where, together with other entities in the scientific system and a company in the meat sector, we have carried out proofs of concept in the development of innovative products in three different lines. In addition to this, we are also involved in two Bioeconomy projects: the RN21 project where we seek to test the behavior of biofilms and the application of rosin resulting from resins from our forestry industry to replace commercial films of fossil origin; and the BE@T Project in which we seek to find industrial symbioses between the by-products of the textile and clothing sector and the by-products of the meat sector. In all three projects, we already have prototypes of new products with promising results and potentially interesting to enter the market. In addition to these projects in progress, we still have some applications under evaluation with the Association of Limousine Breeders and the Municipality of Fundão in order to provide a set of services in terms of training yield for cutting beef carcasses. How do you classify the national meat-producing and processing sector?Portugal’s national meat-producing and processing sector can be classified as a strategic and evolving sector, with characteristics that combine tradition, recognized quality, and challenges in terms of innovation, competitiveness, and sustainability. In these short four years of TECMEAT’s existence and contacts and partnerships already established, I note that there has been an effort to evolve in terms of the adoption of new practices of innovation activities, both in the productive sector and in the manufacturing sector. We all know that, in general, the meat industry is still known to be closed and reluctant to cooperate in the development of new products and processes. However, I have witnessed during these years the effort that these companies are beginning to make to change this paradigm because they are beginning to realize that their evolution, as well as the possibility of increasing their export quotas, will only be achieved through cooperation, innovation, and, above all, the differentiation of products with higher added value. The sector is indeed dominated by small and medium-sized enterprises (SMEs), both in production and processing, which results in fragmentation that can hinder international competitiveness, facing difficulties in competing with large producers in other countries due to the lack of economies of scale and relatively high production costs and more recently the shortage of skilled labour, But it is also true that the sector has great growth potential, as long as it manages to overcome its challenges in terms of innovation, sustainability and competitiveness. What do you consider to be the strengths (and those to be improved) of the Portuguese meat-producing and processing sector? To what extent can TECMEAT help change the scenario?Undoubtedly, one of the strong points of the sector is the quality of the meat we produce. Portugal is known for the production of high-quality meats, especially in the case of pork (including the iconic black pork) or beef through its native breeds such as Limousine, Barrosã, Arouquesa,… just to mention a few. Many companies have also invested in modern technology in the slaughtering and processing processes, which increases the efficiency andtraceability of products. There has also been a growing focus on the automation (and even robotization) of processes and the innovation of some products. In terms of points to improve, we undoubtedly need to increase training and continuous qualification in new technological practices as well as to increase innovation and cooperation activities between companies and scientific entities. In all